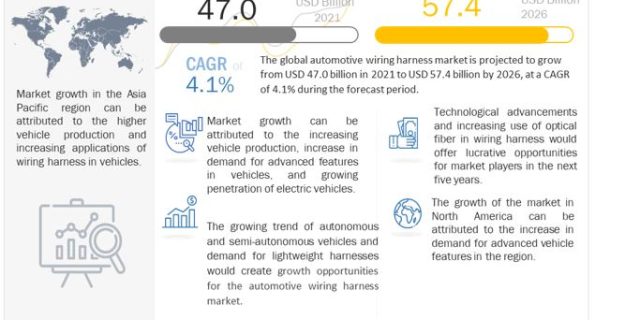

The global Automotive Wiring Harness Market is projected to grow from USD 47.0 billion in 2021 to USD 57.4 billion by 2026, at a CAGR of 4.1% during the forecast period. Increasing vehicle production, increase in demand for advanced features in vehicles, and growing penetration of electric vehicles are the major factors driving the growth of the automotive wiring harness market.

However, a projected recovery in Q1-Q2 of 2021 in vehicle production supports the growth of the automotive wiring harness market. According to the OICA (Organisation Internationale des Constructeurs d’Automobiles), passenger car production hit 55.83 million in 2020, with the Asia Pacific and North America estimated to be the leading regions.

Chassis harness segment is expected to be the largest segment during the forecast period

The chassis harness segment is estimated to lead the market, in terms of value, during the forecast period due to higher demand for automotive wiring harnesses in chassis applications such as frame, air brake pump, suspension systems, and others. Increased demand has encouraged the manufacturers of automotive wiring harness and other component manufacturers to offer technologically advanced chassis harness that helps in short distance and less in weight. Growing demand for premium vehicles and integration of advanced technologies in vehicles are expected to increase the demand for automotive wiring harnesses.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=170344950

The metallic segment by material type is expected to hold the largest market share in 2021

The metallic segment holds the largest share in the automotive wiring harness market. OEMs mostly use copper for manufacturing automotive wiring harnesses due to high conductivity, limited corrosion, high tensile strength, and high data transfer. Despite fluctuations in the prices of copper, which have impacted the profit margins of wiring harness manufacturers in the recent past, metallic materials are still expected to hold a 92% share in the automotive wiring harness market by 2026.

Asia Pacific is estimated to be the dominant regional market

China is major contributor to the overall automotive wiring harness sales (approximately 60%) in the Asia Pacific region in 2021.

China is considered the manufacturing hub for the automotive industry. According to the MarketsandMarkets, China and India together produce approximately 25 million vehicles every year. With an increase in production of vehicles, the demand for automotive wiring harnesses is expected to increase. This, in turn, is expected to drive the growth of the automotive wiring harness market in the Asia Pacific region. China is estimated to dominate the Asia Pacific automotive wiring harness market during the forecast period. China is the world’s largest vehicle manufacturer. Thus, the market for automotive wiring harnesses in China is estimated to grow at a high rate. OEMs based in China are focusing on the adoption of lightweight materials for wiring harnesses. Thus, wiring harness manufacturers are increasingly using materials such as aluminum. Currently, there is limited penetration of aluminum in wiring harnesses.

In the past few years, the Asia Pacific region has experienced an increase in demand for luxury vehicles. The luxury/premium segment vehicles are equipped with advanced body electronic functions that require additional automotive wiring harnesses for proper functioning. Thus, the region is estimated to dominate the automotive wiring harness market with a 57.6% share in 2021.

Key Market Players:

Yazaki Corporation (Japan), Sumitomo Electric Industries (Japan), Aptiv PLC (Ireland), Furukawa Electric (Japan), and Leoni AG (Germany) are the prominent players in the automotive wiring harness market. These companies adopted new product development, and acquisition to gain traction in the automotive wiring harness market.

To speak to our analyst for a discussion on the above findings, click Speak to Analyst