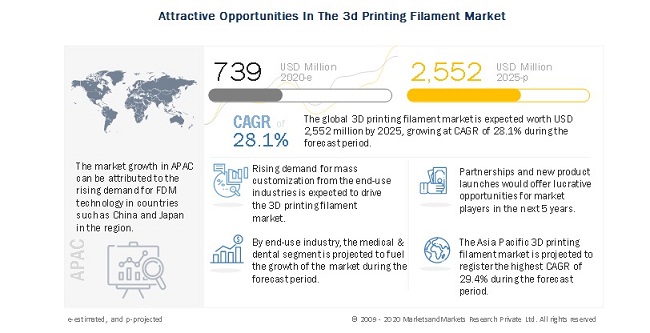

The 3D printing filament market is estimated at USD 739 million in 2020 and is projected to reach USD 2,552 million by 2025, at a CAGR of 28.1% from 2020 to 2025. The plastics segment is estimated to lead the 3D printing filament market in 2020, owing to increasing demand ABS and PLA materials to print objects across the end-use industries. In addition,high demand for plastics in the production of medical components and devices due to outbreak of COVID-19 is anticipated to fuel the growth of 3D printing filament in the plastics segment. 3D printing filament has played an important role in the production of medical components such as swabs, face masks, and ventilator splitters.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=267169690

Major companies such as Stratasys Ltd. (US), 3D Systems Corporation (US), Koninklijke DSM N.V. (Netherlands), Materialise NV (Belgium), Evonik Industries AG (Germany), Arkema SA (France), Saudi Basic Industries Corporation (SABIC) (Saudi Arabia), DuPont de Nemours, Inc. (US), BASF 3D Printing Solutions GmbH (Germany), HP Inc. (US), EOS GmbH – Electro Optical Systems (Germany), Shenzhen Esun Industrial Co., Ltd. (China), CRP Technology S.r.l. (Italy), EnvisionTEC GmbH (Germany), Oxford Performance Materials, Inc. (US), and MG Chemicals (Canada) among others are key players in the 3D printing filament market. These players have been focusing on developmental strategies, such as acquisitions, partnerships, collaborations, expansions, agreements, and new product developments & launches, which have helped them expand their businesses in untapped and potential markets. They have also been adopting various organic and inorganic growth strategies, such as agreements, new product developments, acquisitions, and partnerships, to enhance their current position in the 3D printing filament market.

Stratasys Ltd. is one of the leading providers of 3D printing solutions for rapid prototyping and direct digital manufacturing (DDM). It also develops, manufactures, and markets materials such as metals, plastics, and ceramics for the 3D printing marketplace, along with the related services. The company provides two major 3D printing technologies: Fused Deposition Modeling (FDM) and PolyJet. As of 31 December 2019, Stratasys held approximately 1,000 granted patents and has approximately 500 pending patent applications worldwide.

- In April 2020, Stratasys Ltd. entered into strategic partnership agreement with Origin to offer 3D printed nasopharyngeal swabs to the healthcare sector. Under this partnership, the company markets and promotes Origin 3D printed nasopharyngeal swabs to healthcare providers and testing centers in the US. This partnership is expected to help the company to improve its market position in the healthcare sector and expand its business applications.

- In April 2020, MakerBot, a subsidiary of Stratasys Ltd. and global leader in 3D printing expanded its METHOD materials portfolio with the addition of PC-ABS and PC-ABS FR specialty materials for functional prototyping and end-use applications. MakerBot rapidly expanded its industrial-grade materials for the METHOD platform and focuses on delivering a wider range of industrial-grade solutions for additive manufacturing applications.

3D Systems Corporation offers comprehensive 3D printing solutions and is a leading global additive manufacturing solutions company. The company continues to develop new materials across its plastics portfolio to address a broader set of production applications. Further, 3D Systems has planned several innovations for its plastics materials portfolio designed to help manufacturers address a broader portfolio of applications. It offers its 3D printing solutions to markets such as aerospace, automotive, medical, dental, and consumer goods.

- In February 2020, 3D Systems Corporation extended its agreement with Sanmina Corporation (US) for the manufacture of certain plastic 3D printing platforms. The company already has an ongoing relationship with Sanmina for the manufacture of the Figure 4 platform. With this extended agreement, the company further focuses on its core competencies on plastics materials and application development.

- In March 2020, 3D Systems Corporation is helping medical device manufacturers and hospitals in fighting the COVID-19 pandemic. 3D Systems Corporation has partnered with Isinnova (Italy) to produce 100 valves enabling creation of emergency ventilator masks.

Koninklijke DSM N.V. (Royal DSM) is one of the key players in the 3D printing filament market. The company offers different types of 3D printing materials under different brands, namely, Arnite, Arnitel, and Novamid. The company supplies 3D printing plastics for prototyping and other applications. It is making efforts to enhance its product range by adding new materials, especially thermoplastics, to its product portfolio. The company’s operations network spans more than 110 commercial production facilities in over 40 countries.

- In June 2020, Koninklijke DSM N.V. entered into an agreement to take over certain parts of Clariant AG’s (Switzerland) 3D printing business portfolio to expand rapid market-driven product development solutions. DSM acquired the 3D printing materials business of Clariant that allows DSM to provide rapid product development iterations for high-performance filaments and pellets based on application needs. The strategy enables DSM to strengthen its engineering grade filament, pellet, and powder portfolio.

Speak to Analyst @ https://www.marketsandmarkets.com/speaktoanalystNew.asp?id=267169690

Impact of COVID-19 outbreak on the 3D printing filament market

The COVID-19 outbreak started from Wuhan in China has spread across all the major economies in the world. The 3D printing filament market has been slightly impacted due to the outbreak of COVID-19 as most of the 3D printing filament s production plants are located in the countries that are highly impacted due to coronavirus. Also, major manufacturers of 3D printing filament have their headquarters and principal subsidiaries in the impacted countries. The disruption caused by the COVID-19 outbreak has impacted the supply chain of the 3D printing filament market due to low demand and as the production has slowed down in many manufacturing units of the end users.

However, 3D printing filament manufacturer are offering their products for printing objects for medical applications following the rapid demand for medical components and devices such as swabs, face masks, and ventilator splitters, among others. Several end-users have shifted their production focus towards the production of medical emergency requirements. This opens opportunities for new application areas of 3D printing filaments in medical industry.

Get 10% Customization on this Report @ https://www.marketsandmarkets.com/requestCustomizationNew.asp?id=267169690